Top Performance Atlas Copco Air Motors available here at Total Air Tool Services.

Here at Total Air Tools we have a wide range of Atlas Copco Air Motors available. With power yields from 0.1-6.5 kW, our air motors are minimal and dependable with high energy to-weight proportions. Our Atlas Copco Grease free air motors are accessible in sizes up to 300 W. Stainless steel air motors are additionally accessible, perfect for the food and chemical businesses because of their ability to withstand destructive situations. Notwithstanding the standard range Total Air Tool Services can offer bespoke Atlas Copco air motors adjusted to individual client’s requests.

LZB Standard

This is the most comprehensive range of air motors we offer. With the vast number of different gear versions one is likely to find a motor that fits most application. The standard LZL can be found in most applications globally. With a body in aluminum and nitrocarurated steel for good corrosion resistance, high precision cut gears and high quality seals the LZL is designed to meet the toughest requirements on durability, productivity as well as controllability.

The eight models we have in the LZB Standard range are basically a split of the available almost 250 versions depending on their power/size. From the smallest 0,11 kW (0,15 hp) to the strongest 2,8 kw (3,75 hp) the following versions are available:

Rotation – Clockwise rotation, Anti clockwise rotation and Reversible

Shaft – keyed or threaded are our standard versions

Stainless Steel LZB

For applications that expose the air motor for high moisture/water, corrosive substances or are in the need for regular cleaning and should be without dirt pockets – LZB in Stainless Steel is the right choice.

Here the complete housing as well as the outgoing shaft and gear rim are made in Stainless Steel. In the Stainless Steel range you can chose between clockwise rotation and reversible. All shafts are keyed as standard.

LZB with brake module

For applications where there is a need to lock the motors outgoing axel when the motor is without air, we do offer a range of brake module equipped motors. The brake serves usually as a safety to prevent turning/movement when the air motor lacks air pressure.

In order to get the axel to turn again, air pressure needs to be available in the motor – hence the brake can be released and the motor can then turn.

Low speed and low torque LZB

For applications where low speed is required there are two sizes designed for this purpose. Both are available in steel/aluminum or in Stainless Steel. All versions are reversible and comes with a keyed shaft.

Note: Maximum permitted torque is 9 Nm (6,6 lf-ft) respectively 14 Nm (13,3 lb-ft). The reason for this limitation is that the gear box will be overloaded if this torque is exceeded.

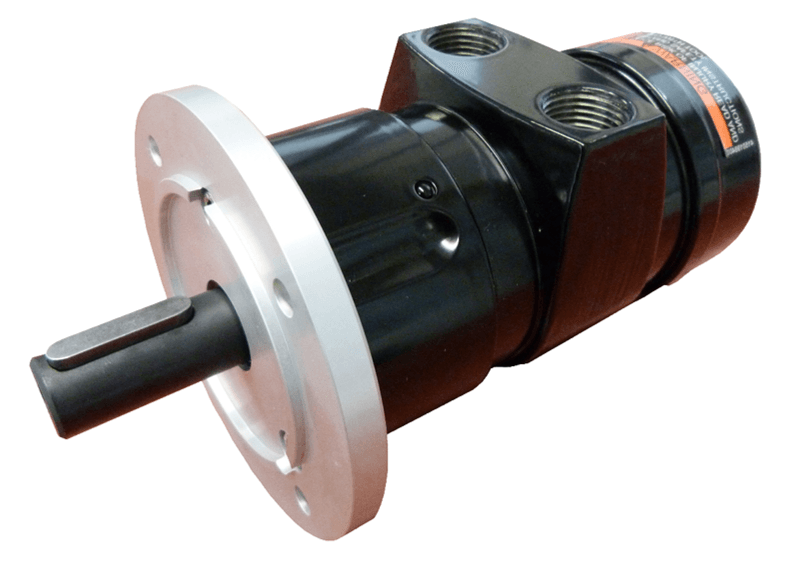

LZL direct driven vane air motor

Divided in to 5 different sizes this direct driven motor is strong, robust, and can be fitted with three different standard flanges, IEC, NEMA and AC (Atlas Copco standard). Choose the size that match the application need and then select the flange that makes the easiest installation.

In addition we have one size that is made of Stainless Steel for applications with tough/harsh environments where extra corrosion protection is needed. The running characteristics of this motor type is strong starting torque and very good low speed performance. For applications such as mixers there are versions with spring loaded vane pins to ensure even better starting and low speed performance. The shaft design, with strong bearings allows the motor to be mounted directly on to the drive shaft without the need of extra shaft support that commonly is needed with other motor designs.

The lubrication free vanes enables the motor to operate in demanding environments that doesn’t allow oil to be in the air/process. All motors are ATEX certified to allow operations in areas where gas or dust are expected. Depending on the application do select the motor that match the ATEX demands.

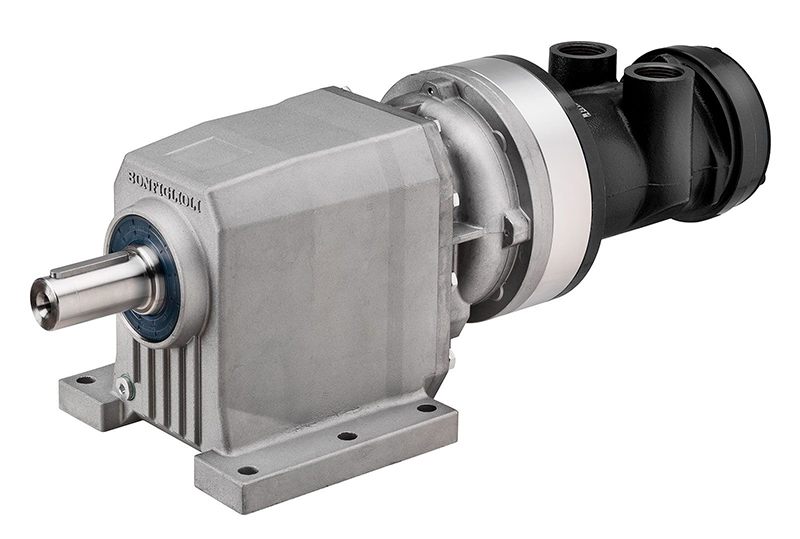

LZL with Helical Gear

In order to adjust the output speed/torque range of the LZL-motors we offer a wide range of gear mounted motors. The motor is direct mounted to a Helical Gear that transforms the motors output to an application suited speed/torque. The output depends on the gear ration within the helical gear. To select the right motor-gear for your application start by selecting a suitable power. If the wanted speed/torque is available within this power range, perfect. If not, do look in to the smaller or bigger motor.

The gears comes in two versions: foot or flange mounted with a speed range from 512 to 17 rpm and torque up to 1836 Nm. For detailed technical information on the products, please click/download on our Air Motor Catalog here below. In addition to the motors we offer vane kits, both lube free and vanes that need lubrication. Also several kinds of silencers can be offered.