MicroTorque MTF6000 Controller

Smart, connected and efficient

The MicroTorque MTF6000 Controller from Atlas Copco takes productivity, quality and connectivity to entirely new level, leading your low torque production into through the Industry 4.0 revolution. MTF6000 minimizes and eliminates set up time, helps you to reduce cycle time keeping high quality, allows you to customize your strategy for any type of screwed joint and combine and put multiple tightening programs in the right sequence for your process, sometimes eliminating the PLC. With a user-friendly software interface, and the power to easily analyze and configure improvements, it makes complex processes simple.

Features

- Compact and lightweight

- Advanced tightening strategies

- Workflow instructions with batch sequence

- ToolsNet 8 connectivity

- Multi communications with Ethernet, RS232 and fieldbus

- Industry 4.0 revolution-ready

Benefits

- Secure product quality, e.g. by eliminating floating screws and stripped joints

- Increased uptime

- Improved productivity

- Reduction in energy use

- Improved process control and reduced setup time

Handheld current controlled screwdriver

Smart, connected and efficient.

Here are the hard facts:

- It’s smart

- It’s connected

- It’s efficient

- Cost reducing

- Operator friendly

- Error proofing

Fixtured current controlled screwdriver

Smart, connected and efficient.

Here are the hard facts:

- It’s smart

- It’s connected

- It’s efficient

- Cost reducing

- Automation friendly

- Error proofing

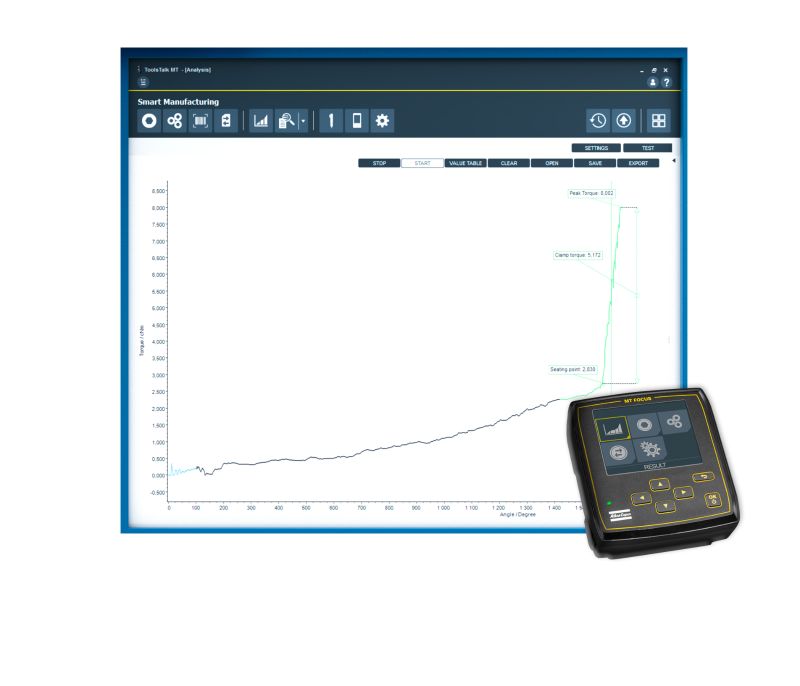

ToolsTalk MT Software Download

Get the latest version of ToolsTalk MT

- Only available on desktop

- ToolsTalk ACTA MT is included

QA Station MicroTorque

An all-round low torque QA solution for higher traceability

Incorporated with efficient and innovative ways of use, QA Station MT can easily activate a pre-defined torque verification program with real-time QA statistic calculation. It enhances the traceability of the quality assurance process with more useful data (tool/controller info, station ID, combined tightening & QA result) which can be easily exported in a digital report, making the whole QA and equipment maintenance process more efficient, error proofing and transparent. QA Station MT also provides the possibility for full automation integration.

Features

- Real-time Quality Assurance statistic calculation with batch track

- Digital result report with useful QA data

- Highly flexible and agile with 16 hour battery time

- Easy activation of torque verification via USB sync and barcode scan

Benefits

- Enhance traceability and visibility for your quality assurance process

- Improve QA efficiency with real-time statistic calculation & digital reporting

- Increase uptime with possible automation integration

MTF6000 Portable Station

A highly agile and flexible low torque tightening solution for higher productivity

The MTF6000 Portable Station is smart, flexible and agile, catering to special tightening needs of electronics customers. It has intelligent advanced tightening strategies to remove floating screws & stripped joints. With high mobility and versatility, it is suitable for repair and maintenance of production equipment in factories. The portable station is also perfect for operators to do tightening around the main products freely.

Features

- Torque, angle and clamping torque monitoring

- Advanced tightening strategies: Torque Seating Monitoring and Seating Control Strategy

- Complete workflow control (batch sequence

- Multiple communication ports and protocols

Benefits

- Secure product quality, reduce rework & scrapping cost

- Enhance traceability and detection of tightening errors

- Error proofing with the elimination of floating screws and stripped joints

- Improve productivity and reduce setup time

- Industry 4.0 revolution-ready design

MicroTorque transducerized smart electric screwdriver

The ETD MT is our all-in-one solution of productivity and quality with smart tightening strategies and superior torque accuracy. Ready for the Industry 4.0!

The MicroTorque’s transducerized handheld screwdriver range ETD MT – an enhancer to further drive transformation of Industry 4.0 and smart manufacturing in your production process.

Being smart, interactive and precise, ETD MT is an impeccable solution to increase productivity and quality.