Speed. Efficiency. Accuracy. The power of innovation.

Extremely reliable and accurate tools that, thanks to their innovative torque control systems with automatic and immediate air shut-off, guarantee very high torque repeatability in the presence of hard and soft joints. Important improvements of the quality of the assembled product allow consequent reduction of the quality controls at the end of the assembly process.

Air shut-off screwdrivers/nutrunners with pneumatic pick-up signal

0% error. 100% accuracy.

These screwdrivers/nutrunners with TOM computerized monitoring unit are practical and simple monitoring systems poka-yoke type (anti-error system) counting good and no-good screws thanks to the “screws counting” function. In case of high production rate you won’t risk any missing screw.

To view our Screwdrivers/Nutrunners with air shut-off in more detail and to also see our brochures, please click the following desired model.

Triple air inlet, pistol grip models

Freedom of movement, versatile in use

Brand new screwdrivers designed for air supply from three different points and with lever operated reversibility next to the start button : to use the screwdriver in the best possible way according to the size of the component and operating layout and for quick and practical change of rotation through lever buttons being activated with the same hand.

Computerized unit for torque monitoring

TOCS-TC

TOCS-TC (Tightening Operation Control System – Torque Control) defects and stores the tightening torque value, displays the cycle results (OK and KO) and monitors the tightening cycle through torque/time values, that can be easily stored • Up to 20 programme settings (MIN torque, MAX torque, MIN time, MAX time) and password protection • Tightening sequences settings with a maximum of 99 screws and a maximum number of repetitions in the event of a reject. The I/O offer: • OK/KO signalling for each cycle and general OK/KO (end-of-sequence) • 3 user configurable on-line printing modes • The type of possible rejects required can be detected through the programming of tightening cycle • The internal memory stores torque/time/result data concerning the last 1,000 tightening cycles • The system can be networked (proprietary protocol) with supervision (programming + data acquisition) and optional software • Visual indicators for signalling tightening status, located on the front panel + pallet release signal • I/O connectors for connection to PLC and/or signal lights

Angle Models

Flat Head Drive Models

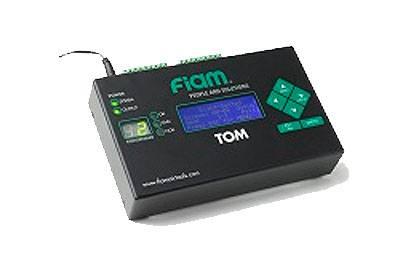

TOM – Process verification system

TOM from Fiam: the intelligent simplicity

TOM, the brand monitoring unit from Fiam, checks the status of the tightening process in real time and guarantees reliability regardless of the skill of the operator. This practical and economic Poka Yoke system, leaving no room for mistakes, gives the operator feedback on the success of the tightening operation once completed, so he can then move swiftly on to the next working stage.